You are here: Tutorials > Transient Motor Starting (TMS)

EasyPower® Tutorial - Transient Motor Starting (TMS)

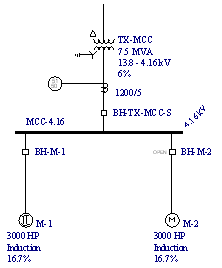

The Transient Motor Starting (TMS) feature of EasyPower enables you simulate various power system events like motor starting, device switching, and bus

faulting. It supports calculating voltage, current, speed, torque, and power for motors at various locations using

EasyPower’s dynamic models. These calculated values are shown in time plots, spreadsheets and the one-line.

To perform the steps in this tutorial, open the DSExample-1.dez file located in the Samples folder.

TMS Data

Items on the one-line must have TMS data before you can run dynamic simulations.

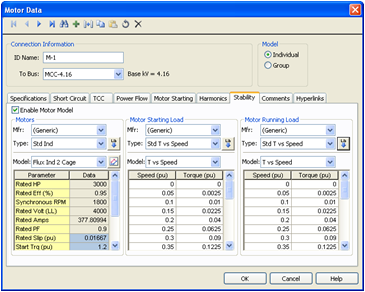

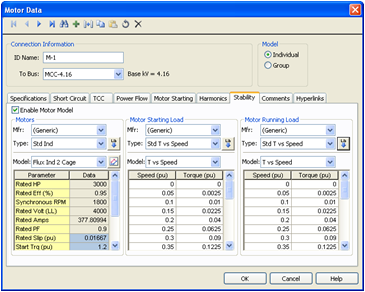

- Double-click on the motor M-1 to open the Motor Data dialog and set the TMS data, as follows:

- Select the Stability tab and select the Enable Motor Model check box.

- In the

Motors section, select (Generic) for

Mfr and Std Ind for

Type as shown in the figure below.

- Click

Library to import the motor stability data from the library.

Library to import the motor stability data from the library. - A message is displayed asking if you want to overwrite EFF and PF with Dynamic Data. Click

No. This retains the efficiency and power factor data from the specifications tab.

- Under

Motor Starting Load, select Generic for Mfr and Std T vs Speed for Type, and then import the data as you did above.

- Under

Motor Running Load, select Generic for Mfr and Std T vs Speed for Type, and then import the data as you did above.

Figure 1: Motor Stability Data

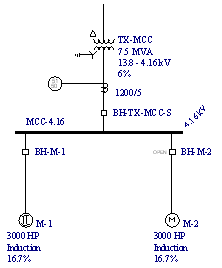

- Click OK. The motor symbol on the one-line changes to that shown in Figure 2 below.

- Load

Stability data for motor M-2, just as you did for M-1 above.

- To display the ID Names for breakers on the one-line, in

Tools > Options > Text Visibility, in the Show Name For column. select the HV Breaker check box.

Figure 2: Motor Symbol in One-line - Compare M-1 to M-2

Running a TMS Simulation

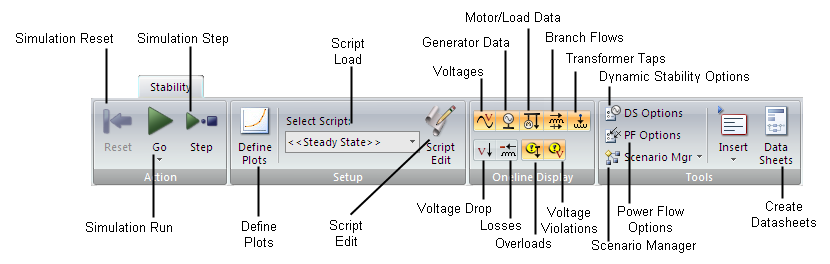

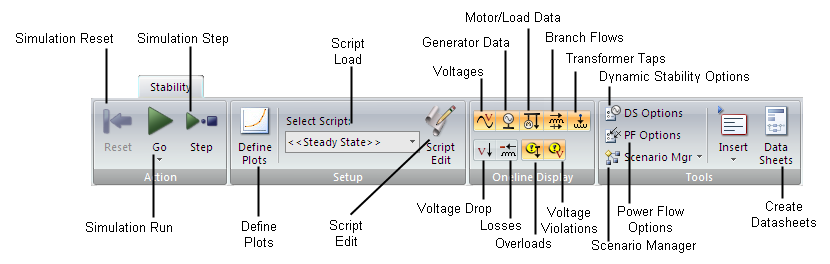

- From the Home ribbon, open the Dynamic Stability focus by clicking

Stability in the ribbon. The Stability ribbon is displayed as shown in Figure 3 and the windows

are arranged to view the one-line, the simulation plot and message log. As you enter the Dynamic Stability focus, EasyPower

runs a power flow solution for steady state. Note the power flow results on the one-line.

Stability in the ribbon. The Stability ribbon is displayed as shown in Figure 3 and the windows

are arranged to view the one-line, the simulation plot and message log. As you enter the Dynamic Stability focus, EasyPower

runs a power flow solution for steady state. Note the power flow results on the one-line.

Figure 3: Dynamic Stability Ribbon

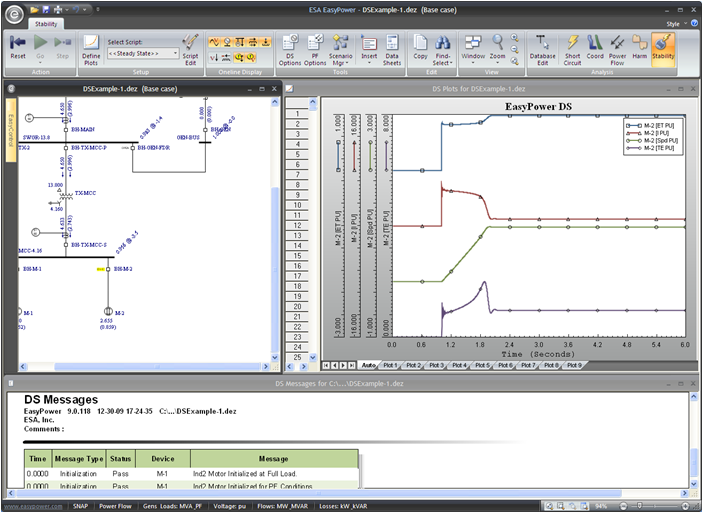

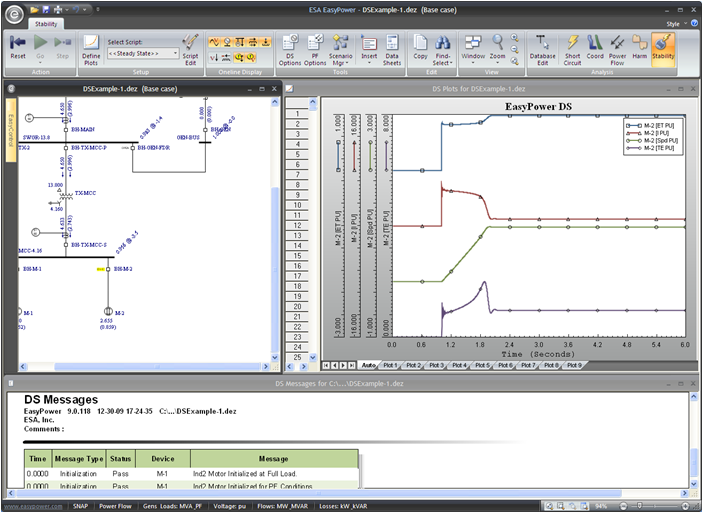

- To simulate starting the motor M-2, double-click on the breaker BH-M-2. The EasyPower window is displayed as

shown below.

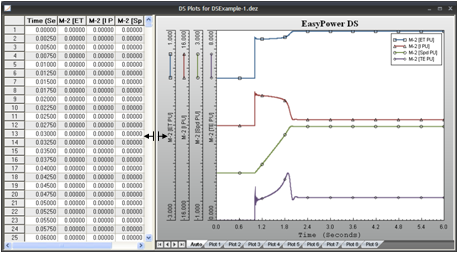

Figure 4: Motor Starting Results

The one-line shows the power flow results at the end of the simulation. The plot on the right shows values of motor voltage,

current, speed and torque plotted against time. The message log window at the bottom describes what processes or events occurred.

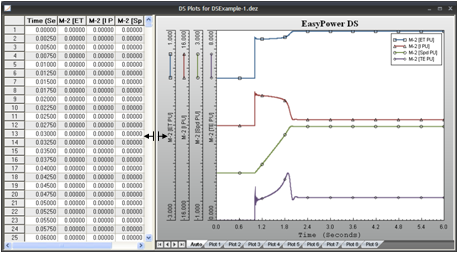

To view the spreadsheet data for this plot, you can drag the left edge of the plot area (splitter bar) to the right. You can

format the plot axes or the plot area by double-clicking on the item.

Note: To perform any simulation commands, the one-line window must be the active window (selected

or current window). If your one-line window caption is not highlighted, click it to make it active.

Figure 5: Simulation Data in Spreadsheet

Dynamic Simulation Options

Click on the one-line window and select

DS Options from the

Stability ribbon. You can control the simulation through options in this dialog box.

DS Options from the

Stability ribbon. You can control the simulation through options in this dialog box.

In the

Double-Click Control tab, note the controls for

Breaker or Switch to Close. The default values are 6 seconds for

Simulation End Time and 1 second for

Delay Time Length. In the plot from the previous simulation, notice that the breaker BH-M-2 closed one (1)

second after the start of the simulation, and the simulation plot ends at 6 seconds. You can control other double-click actions

like bus faulting and ATS transfer in the same way.

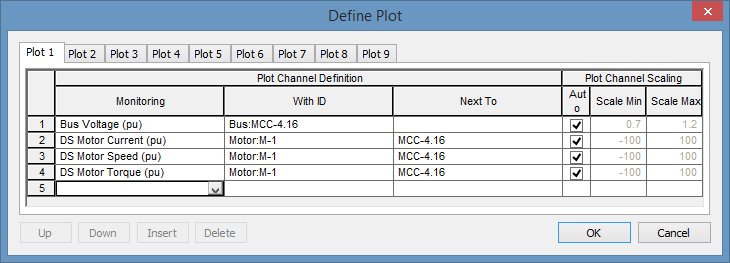

Plotting User Selected Values

When you perform a simulation by double-clicking on the one-line, data is plotted in the AutoPlot tab. Based on the type of

simulation, EasyPower chooses which values to display in the AutoPlot. In the previous example, the plot was provided with

motor per-unit values for voltage, current, speed and torque. To see values elsewhere in your system, you need to define plots.

Nine plots are available with up to a maximum of 5 curves per plot.

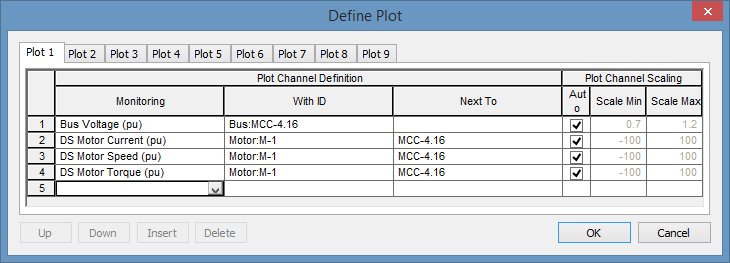

Figure 6: Defining Plots

- To define a plot, ensure the one-line is selected, and then click

Define Plots from the ribbon. When motor M-2 starts, the voltage dip affects values at motor M-1. In Plot 1 we

view voltage, current, speed and torque for motor M-1.

Define Plots from the ribbon. When motor M-2 starts, the voltage dip affects values at motor M-1. In Plot 1 we

view voltage, current, speed and torque for motor M-1.

- Select values to plot by selecting the fields for

Monitoring,

With ID and

Next To, as shown in the figure above. Values can also be selected by first selecting an open

Monitoring cell, and then by right-clicking on motor M-1 on the one-line, and selecting the desired value type to

be plotted with the

Define Plots dialog box open. Click

OK to close the

Define Plot dialog box.

- Click on the

Reset Simulation button to reset to steady state prior to any dynamic simulation. Start motor M-2 again by double-clicking on breaker BH-M-2. Click the Plot 1 tab to view the simulation results.

Reset Simulation button to reset to steady state prior to any dynamic simulation. Start motor M-2 again by double-clicking on breaker BH-M-2. Click the Plot 1 tab to view the simulation results.

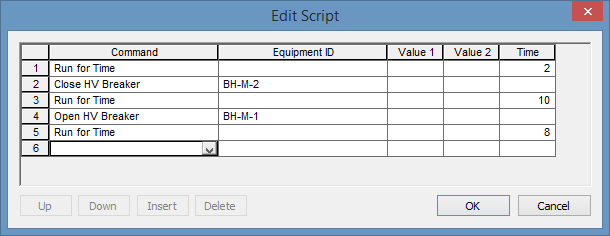

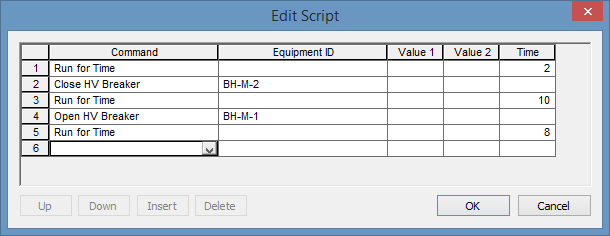

Running a Simulation From Scripts

You can write scripts to simulate various events and run them sequentially. Before we run scripts, we need to define plots so

we can view results for the desired values. Next, we will write a script to simulate steady-state for 2 seconds, starting motor

M-2, and switching off motor M-1.

- First define Plot 2 to view speed, torque, current and voltage for motor M-2, all values in

per-unit, as you did for motor M-1 earlier.

- To write a new script:

- Click

Script Edit in the ribbon.

Script Edit in the ribbon. - Click

New to add a new script.

- Type Start M-2 and Stop M-1 as the name of the new script. Add commands to the

script as shown in the figure below.

Figure 7: Script Example

- Click

OK in the

Edit Script dialog box.

- Click Close in the

Scripts dialog box.

- In the Select Script box in the Stability ribbon, select the Start M-2 and Stop

M-1 script.

- Click

Run Simulation button. View Plots 1 and 2 of the plot window to see the results.

Run Simulation button. View Plots 1 and 2 of the plot window to see the results.

Simulating Faults

On the one-line window, double click on bus MCC-4.16. This runs a simulation of a 3-phase fault on this bus. The fault

impedance and duration can be specified in

DS Options > Double-Click tab. If you have

the PowerProtector™ coordination feature enabled, TMS can simulate the response of a power system to a fault condition

by causing protective devices to trip based on time-current curves. Notice the “C>>O” symbol on the tripped

breaker in the one-line and the fault current dropping to zero in the AutoPlot. The Plot 1 tab shows motor M-1 fault current

contribution and its subsequent spin-down after fault clearing.

Conclusion

This has been a brief tutorial on EasyPower’s TMS program. With PowerProtector™, you can also simulate contactors

dropping out because of excessive voltage drop, or an ATS switching to emergency power. Remember to enter data in the

Stability tab of the various equipment data dialogs as necessary in the Database Edit focus first. Make use of

scripts to simulate sequential events and use the

Define Plots feature to monitor values.

Library to import the motor stability data from the library.

Library to import the motor stability data from the library.