Tutorial - Motor Control Centers (MCCs)

This tutorial provides a brief description of EasyPower motor control centers (MCCs).

Creating an MCC

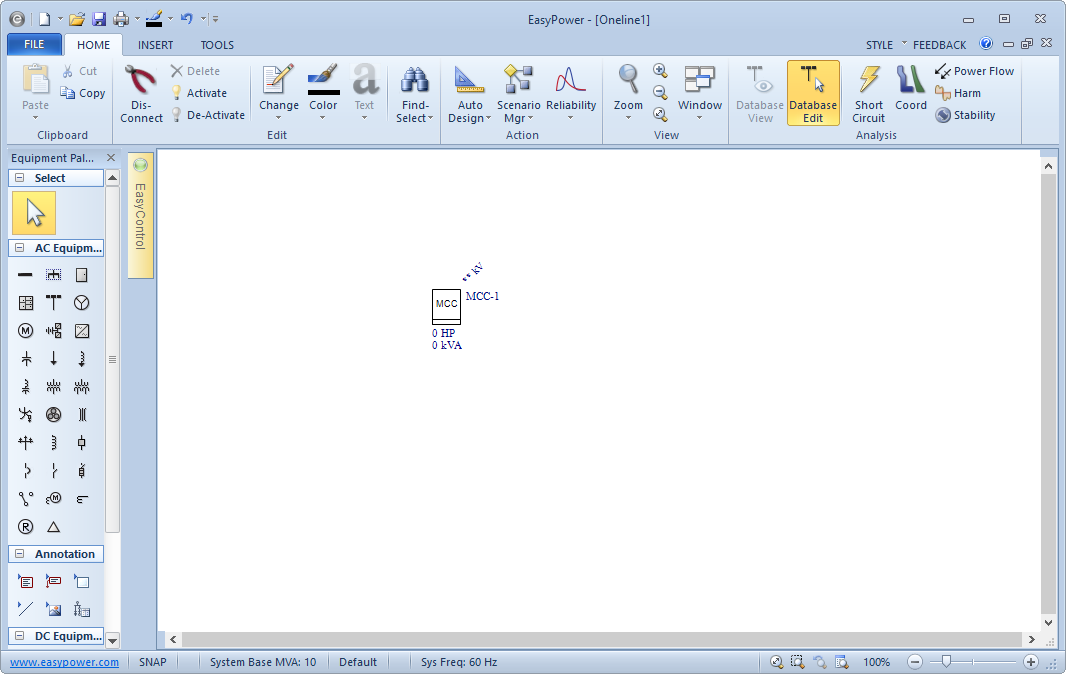

- Open a new one-line by clicking File > New > New Oneline.

- Click

Maximize on the one-line window, if needed, to fill the session window with the one-line.

Maximize on the one-line window, if needed, to fill the session window with the one-line. - In the Equipment Palette, select

MCC. The pointer changes to an MCC symbol. Click anywhere on the one-line to place the MCC.

MCC. The pointer changes to an MCC symbol. Click anywhere on the one-line to place the MCC.

Tip: If you are viewing the Start Page, you can click New to open a blank one-line.

Figure 1: One-line View of an MCC

Depending on your settings, you may need to click  MCC again or click the

MCC again or click the  Select arrow to return to the pointer.

Select arrow to return to the pointer.

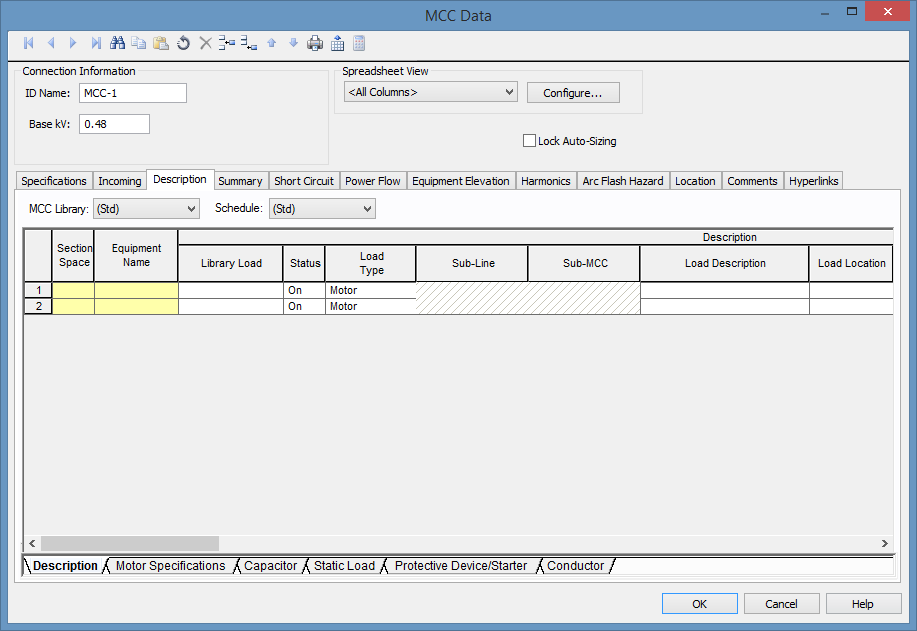

Entering MCC Data

- Double-click on the MCC you just added to the one-line.

- In the Connection Information area, note the red exclamation mark next to the Base kV box, indicating it is required. Type 0.48 into the box.

- Click the Description tab. In the MCC Spreadsheet Creation Wizard dialog box, select 2 as the number of rows you want to create, and then click OK.

In the MCC Data dialog box, note that there are several tabs. The Specifications tab contains entry fields for MCC information. Most of these are not required for analysis calculations. For this tutorial, assume that units are set to US, not Metric.

Note: You can resize the MCC Data dialog box by dragging its edges. You can also maximize the dialog box on your screen by clicking the  Maximize button.

Maximize button.

- Enter data in the MCC spreadsheet just like you would in a spreadsheet such as Excel. The data is validated as you enter it.

Figure 2: MCC Data Dialog Box

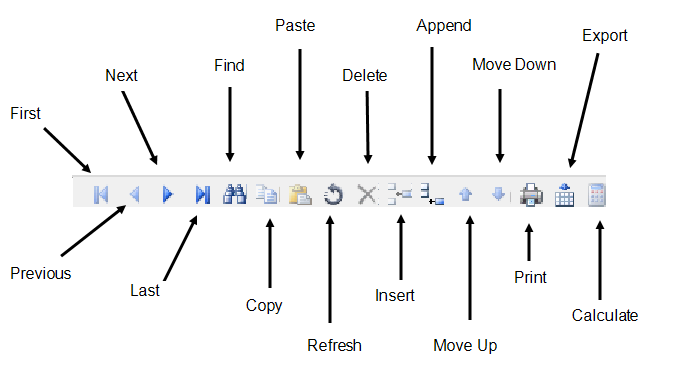

The MCC spreadsheet toolbar includes additional options when you view the Description tab (see below). You must click somewhere in the spreadsheet to make the toolbar buttons available.

Figure 3: The MCC Spreadsheet Toolbar

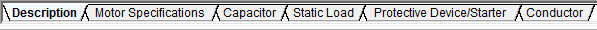

The spreadsheet has its own scroll bars to use for moving around. You can also use the tabs at the bottom of the spreadsheet (shown below) to move to different sections of the spreadsheet.

Figure 4: MCC Spreadsheet Sections

Cells that have inadequate data for analysis purposes are highlighted in red. Notice that the Motor HP cells are red. Each MCC motor must have a motor horsepower for the MCC to be validated for analysis study.

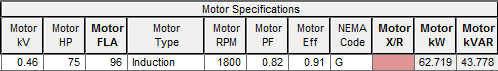

- Under Motor Specifications, make the first motor a 75 Hp motor by entering 75 into the first row of the Motor Hp column. Then click on a different cell so the change is stored.

The Motor Hp cell is no longer red, indicating it now has valid data entered. Also, the Motor kW and Motor kVAR fields are automatically calculated based on the Motor Hp, Motor PF (power factor), and Motor Eff columns. The motor kW and kVAR cells cannot be manually edited.

All cells that can be calculated are indicated by bold column headings. Notice in the image below that the Motor X/R column header is bold.

- Click in the first Motor X/R cell and click

Calculate in the toolbar. The program calculates the X/R value and displays it.

Calculate in the toolbar. The program calculates the X/R value and displays it.

Note: You must have a Motor Hp entered for an X/R to be calculated.

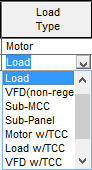

- Under Description, in the Load Type column, select Load. Click a different cell in the spreadsheet so the change is saved.

- Enter 30 kW and 10 kVAR in the Static Load section of the spreadsheet.

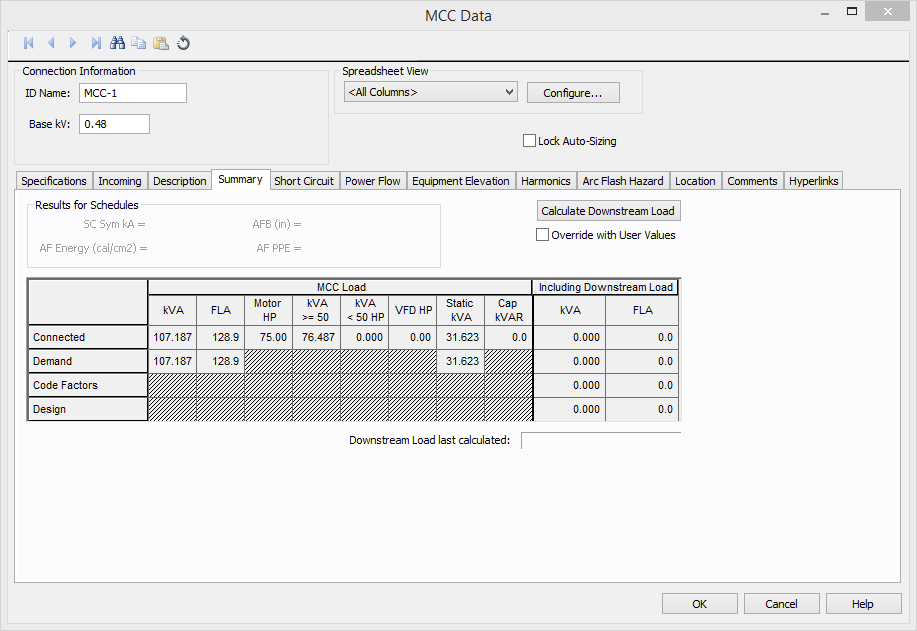

- Select the Summary tab of the MCC Data dialog box. General information calculated from the MCC spreadsheet data is displayed here.

- Select the Short Circuit tab.

- Click Calculate.

- Select the Power Flow tab.

- Click OK to close the MCC Data dialog box.

You can also manually enter the Motor X/R if you do not want to have the number calculated for you.

Figure 6: Load Type Selection

Notice the Motor Specifications cells are no longer available. The Static Load cells are now editable.

Since MCC analysis calculations do not require Protective Device/Starter or Conductor data to be entered for motor and load types, you do not need to do anything with them now.

Under Description, you will notice a Library Load column. This is for advanced MCC spreadsheet users who want to enter typical MCC circuits in their user-editable device library. After predefining a library load in Stdlib.mdb (the device library), selecting that library load in the MCC spreadsheet automatically fills in the rest of the cells for that row.

Figure 7: The MCC Summary

Notice that the motors have been separated into two groups. ANSI standards specify different short circuit impedance multipliers for motors of less than 50 Hp and greater than 50 Hp. See the "Motor Data" section of the EasyPower User Guide or Help for more information. EasyPower combines all the motors of less than 50 Hp and more than 50 Hp and models them as two separate motors in the Short Circuit focus.

Note that there is an Including Downstream Load section. When you click Calculate Downstream Load, EasyPower automatically traverses your system to add up downstream load.

There are no generators in this system yet, so the downstream load is not calculated in this example. In the traversing algorithm, EasyPower uses generators to determine upstream branch direction.

The values in the Short Circuit tab are necessary for the short circuit impedance calculations of the motors in the spreadsheet. You can either calculate the X/R Avg or manually enter an amount.

The Connected kVA is the vector sum of all the connected motor and load KVAs. You have the option of using Demand, Code Factors, or Design kVA values as well.

MCCs in Analysis

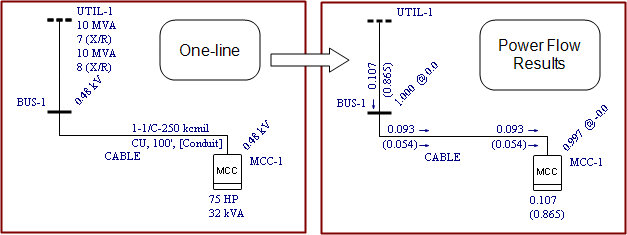

If you are an advanced EasyPower user, you can connect the MCC to a bus through a cable, connect the bus to a utility and have EasyPower perform short circuit, power flow calculations on this small system.

Figure 8: Power Flow Results on an MCC

Conclusion

This has been a brief overview of EasyPower’s motor control center equipment. The EasyPower Help topics cover this and other features in greater

depth. To open Help, click  Help in the upper-right corner of the EasyPower window or press F1.

Help in the upper-right corner of the EasyPower window or press F1.

More Information

| EasyPower® Tutorials |