Performing a Reliability Evaluation

You can perform a reliability evaluation to generate a report and Pareto charts on your system's reliability.

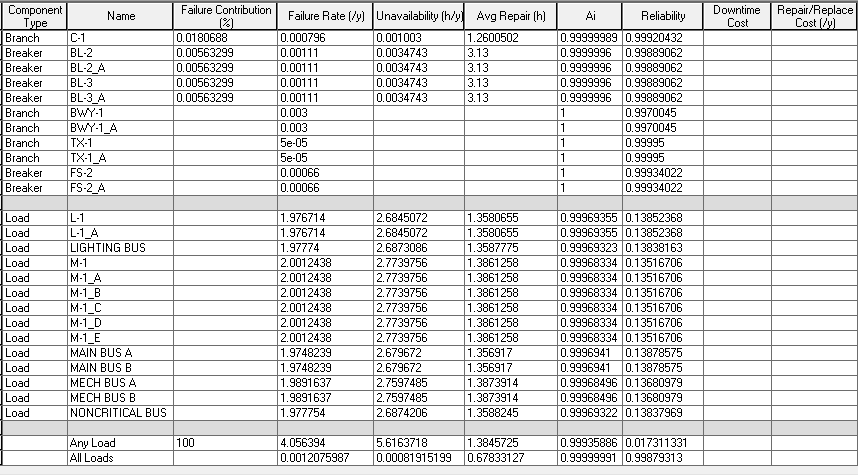

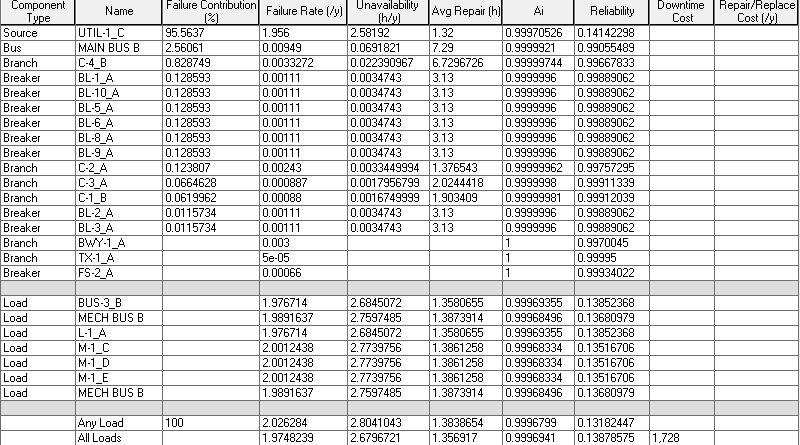

- The report provides details on the failure contribution, annual failure rate, annual unavailability, repair hours, inherent reliability (Ai), reliability, and downtime cost impact for each equipment item, along with an overall total for each of these categories. The total reflects the system reliability on an annual basis.

- The charts provide a graphical representation of failure contribution, failure rate, unavailability, and average repair time.

Note: You must first import reliability data or manually input data before the evaluation can be performed. See Importing Reliability Data and Entering Reliability Data Manually for more information.

To perform a reliability evaluation:

- Click the arrow beneath the Reliability button, and then click Reliability Evaluation.

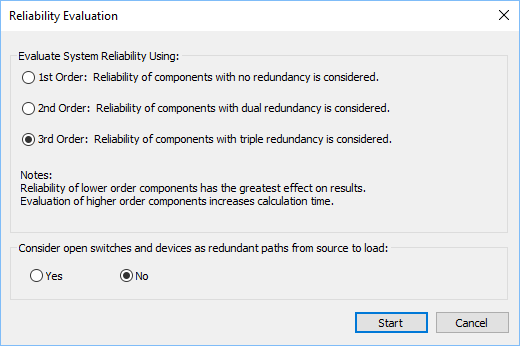

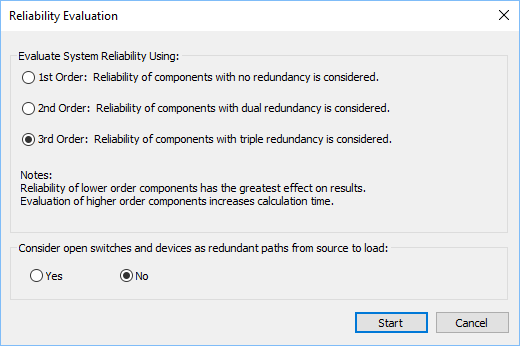

- In the Reliability Evaluation dialog box, you can specify the equipment redundancy to analyze. If you have only a circuit path from source to load, a 1st order redundancy is sufficient. For 2 or more circuit paths from source to load, select 2nd or 3rd order. A 3rd order redundancy takes more time to analyze, but provides a more accurate analysis.

- The program also creates a Reliability Evaluation report.

You can also specify whether to consider open switches and devices when evaluating redundancy. This controls whether open switches or devices and their downstream components are included in the reliability evaluation. The default is to exclude them.

Select the options you want to use, then click Start.

After you have performed the evaluation, you can generate Pareto charts for additional evaluation. See Pareto Charts for more information.

See also: Load Definitions.

Note: Deactivated equipment items are not included in the evaluation.

Additional Methods

Alternatively, you can do either of the following to perform an evaluation:

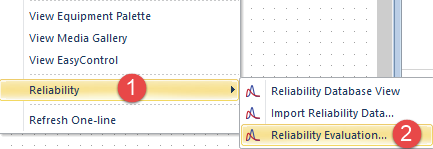

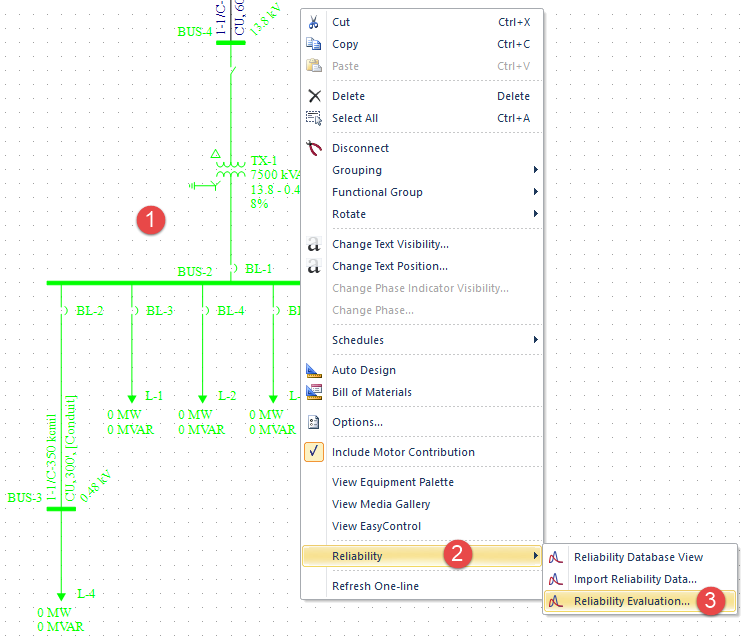

- Right-click on a blank area of the one-line, and then click Reliability > Reliability Evaluation.

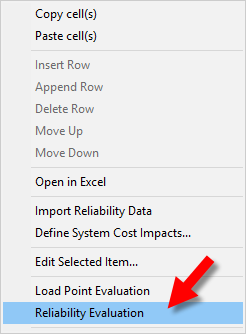

- In the Reliability Database View, right-click on a row, and then click System Evaluation.

Figure 1: Reliability System Evaluation in One-line View

Figure 2: Reliability System Evaluation in Reliability Database View

Evaluating Multiple Items on the One-line

You can also select individual items to have the evaluation run on only the items selected.

- Select the items on the one-line as you normally would. Then, right-click on a blank area of the one-line and click Reliability > Reliability Evaluation.

- Select the redundancy, and then click Start.

- EasyPower displays the reliability for the components you selected.

:

:

Note: You must select a load point, such as a motor, load, bus, MCC, panel schedule, capacitor, shunt, or zigzag transformer.

More Information

| Reliability | Printing Reliability Reports |